When it comes to fastening two or more components together, one of the most reliable options is the use of studs. Studs are preferred because they provide greater strength, stability, and dependability than other fasteners. While there are different types of studs available, the most commonly used ones are full thread studs, double end studs, and tap end studs.

At Industrial Fasteners, we have a wide range of studs to meet our customers’ requirements. Our inventory of studs includes various materials and alloys, such as Hastelloy C276, Carpenter 20, Duplex 2205, 316 Stainless, and 18-8 Stainless (need remove brand name). All our studs are manufactured to meet international standards for quality and performance.

Full Thread Studs

A full thread stud features threads that extend from one end of the stud to the other. They are used in applications where both ends of the stud are required to be threaded, such as in coupling nuts or flange nuts. The length of a full thread stud is measured from the first thread to the last thread, excluding the heads.

We carry a range of full thread studs in different materials to suit various corrosion-resistant and high-temperature applications. Our Hastelloy C276 full thread studs, for example, are suitable for applications that require resistance to harsh environments, such as those found in chemical processing, oil and gas, and power generation.

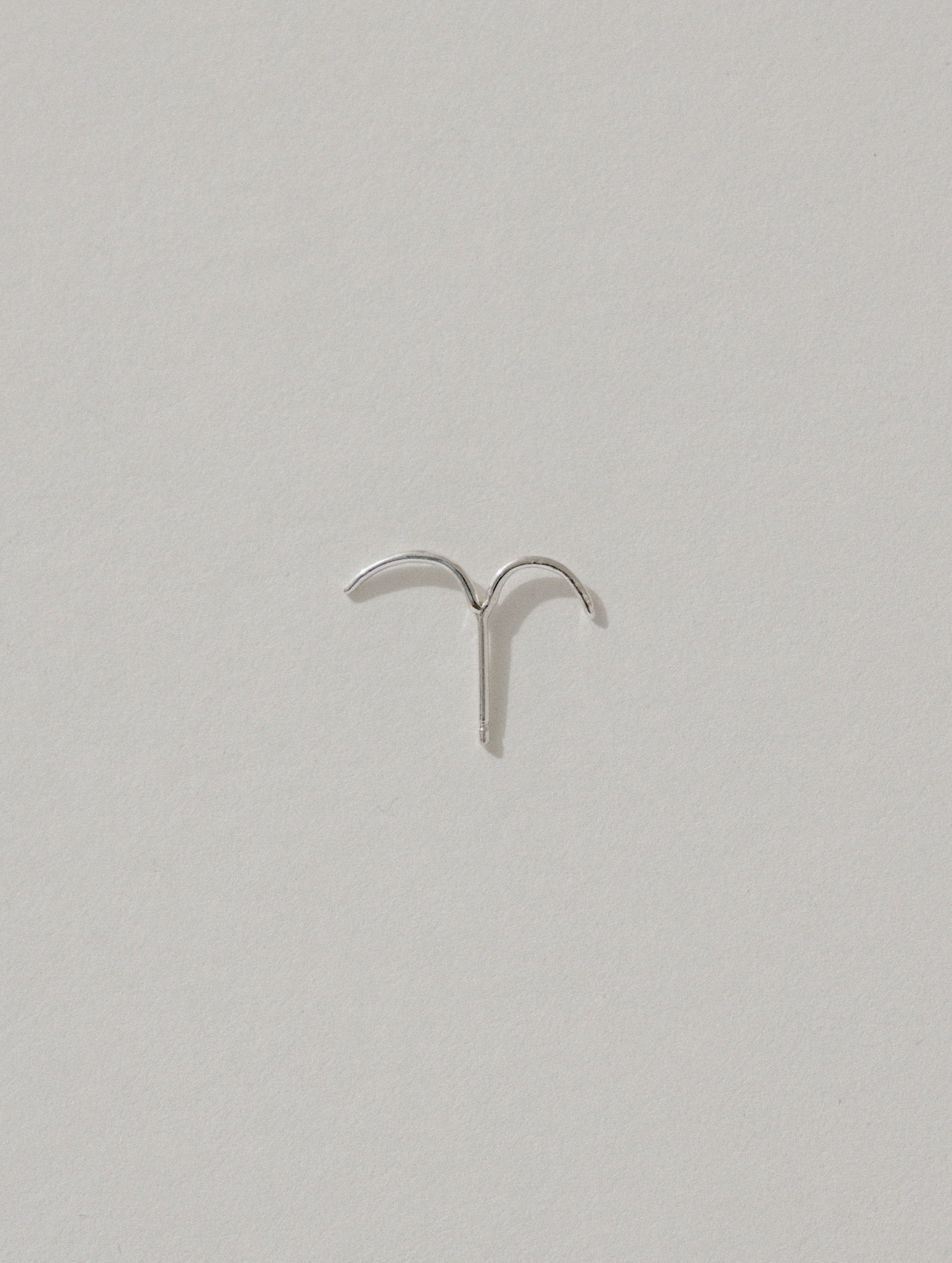

Double End Studs

Double end studs, as the name suggests, feature threads on both ends with an unthreaded portion in the middle. They are commonly used in applications where two components need to be fastened to each other. They can also be used as dowels and pins in alignment applications.

Our inventory of double end studs includes various alloys, such as Duplex 2205 and 316 Stainless, that provide high strength and corrosion resistance. They are typically used in applications that involve exposure to corrosive environments, high temperatures, or high pressure.

Tap End Studs

Tap end studs feature threads on one end and a plain shank on the other. They are commonly used in situations where one end of the stud is required to be tight to the surface, while the other end provides a threaded connection. They are also used in applications where the stud material is too hard to be threaded through.

Our tap end studs are available in various alloys, including Carpenter 20, which offers superior corrosion resistance in environments with sulfuric acid, and 18-8 Stainless, a general-purpose material for low to moderate corrosion applications.

Conclusion

At Industrial Fasteners, we provide an extensive inventory of full thread studs, double end studs, and tap end studs to offer our customers a reliable and efficient fastening solution. We ensure that all our studs meet international standards for quality, which makes them suitable for a wide range of corrosive, high-temperature, and high-pressure applications.

Our inventory includes various alloys, such as Hastelloy C276, Duplex 2205, Carpenter 20, and 18-8 Stainless (need remove brand name), which provides corrosion resistance, high strength, and stability. Whether you require studs for chemical processing, oil and gas, power generation, or general purpose applications, we have got you covered.

In conclusion, if you need a dependable and efficient fastening solution for your application, contact us today.